Summary

Leading two teams at Curb Food, a Swedish ghost kitchen company, I spearheaded a project to improve kitchen operations and facilitate scalability. By addressing user pain points and collaborating with cross-functional teams, we streamlined the KitchenOS software and hardware setup process, resulting in a significant reduction in service time and setup time, paving the way for future growth.

Challenge

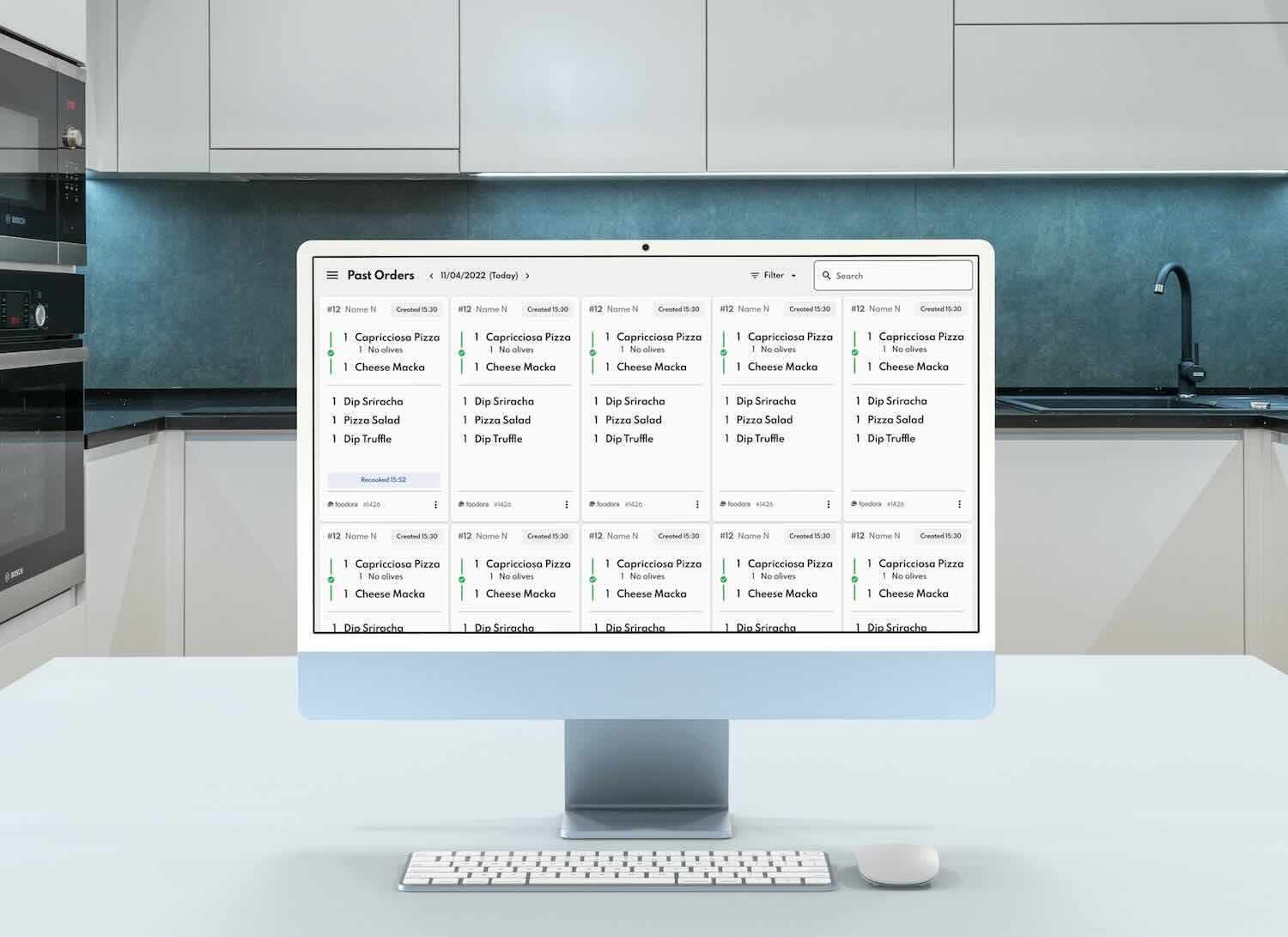

Curb Food’s rapid expansion presented operational challenges in their 18 ghost kitchens. The existing KitchenOS software, while functional, suffered from usability issues that slowed down food preparation. Additionally, the hardware setup process was complex and time-consuming, hindering efficient kitchen deployment. These factors combined threatened to impede the company’s growth trajectory.

My Role

As a Product Manager, I was entrusted with the responsibility of leading two teams totaling 12 FTEs, including designers, front-end and back-end engineers. My primary objective was to identify and address the operational roadblocks hindering kitchen efficiency.

Solution

To tackle these challenges, I employed a multi-pronged approach:

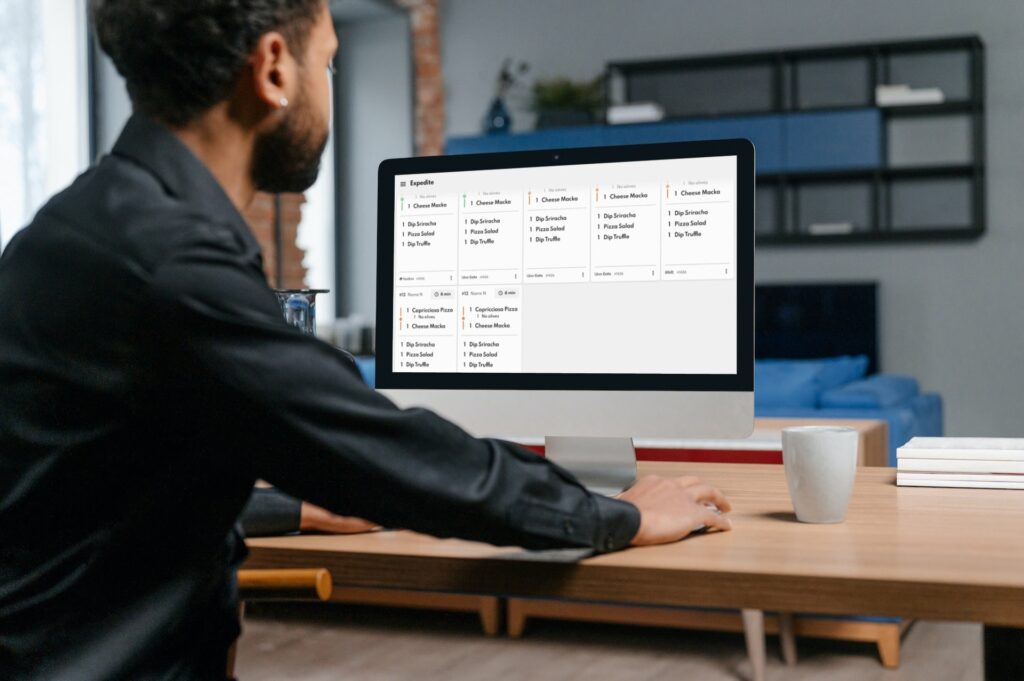

- User-centric research: I conducted extensive user interviews with kitchen staff to gain firsthand insights into their daily struggles with the software and hardware.This initial phase allowed me to prioritize the most pressing pain points and identify areas for improvement.

- Data-driven decision making: I leveraged analytics tools like Amplitude to gather quantitative data on usage patterns and identify areas where the software was causing bottlenecks. This data, combined with qualitative user feedback,provided a comprehensive understanding of the problem space.

- Collaborative development: I fostered close collaboration between the KitchenOS and Pickup Experience teams, leveraging their expertise to develop and test potential solutions. This iterative process ensured that the proposed improvements addressed user needs effectively.

- Streamlined software: Based on the gathered insights, we simplified the KitchenOS interface, making it more intuitive and user-friendly for kitchen staff.Additionally, we addressed critical bugs that were causing delays in food preparation.

- Standardized hardware setup: We developed a more efficient and scalable hardware setup process, significantly reducing the time and effort required to equip new kitchens. This standardization ensured consistency and streamlined future expansion.

Results

The implemented solutions yielded tangible improvements in kitchen operations:

- Reduced kitchen service time per order by over 20%: The simplified software interface and resolved bugs enabled kitchen staff to prepare orders more efficiently, leading to faster service times.

- 80% reduction in hardware setup time per kitchen: The standardized hardware setup process significantly streamlined kitchen deployment, enabling faster onboarding of new locations.

- KitchenOS (software and hardware) ready for future expansion: The improvements ensured that the KitchenOS system was scalable and equipped to handle the demands of future growth.

Conclusion

This case study exemplifies my ability to effectively lead cross-functional teams, conduct user research, translate insights into actionable solutions, and drive measurable improvements that contribute to operational efficiency and support strategic business objectives. The success of this project demonstrates my commitment to user-centric design, data-driven decision making, and collaborative problem solving, all of which are essential qualities for product leaders in today’s dynamic business landscape.